Clive Humby, a UK mathematician, noted in 2006 that

“Data is the new oil. It’s valuable, but if unrefined it cannot really be used.”

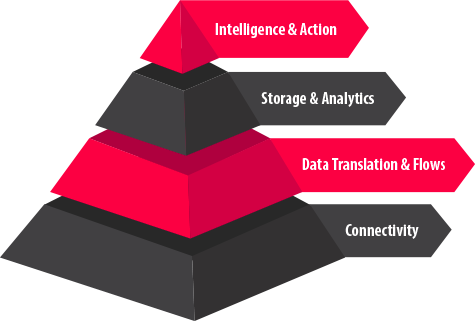

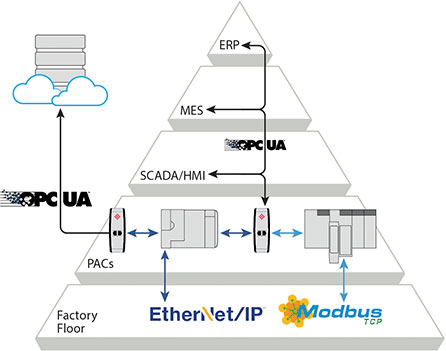

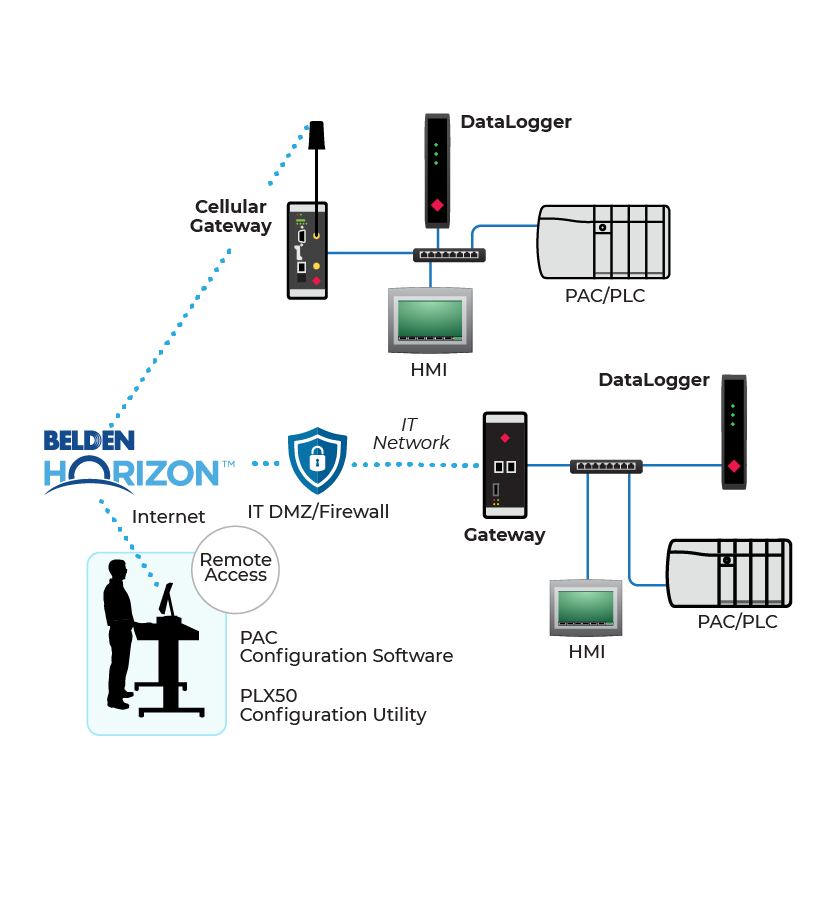

Data can be enormously helpful in your operation and help you realize quantifiable benefits from IIoT investments. Before that point, though, you have to go through the steps to make the data worth its IIoT weight – collect it, transfer the information, refine it, and apply it to your applications. Just like oil.